In recent years, driven by various factors such as policy, technology, market, capital, etc., the development of autonomous driving technology has accelerated, and it has been applied in many industries, bringing huge business opportunities to related enterprises. Changsha Go Further.AI Technology Co., Ltd. (referred to as "Go Further.AI") is a leading provider of autonomous core technologies and smart logistics products in China. It has complete autonomous driving technologies and solutions, and has full-stack independent research and development and design capabilities for chassis, structure, hardware, and software. At present, the company's autonomous robots have been commercially implemented in multiple scenarios such as express delivery, factories, and community/office parks. Among them, the application projects of two different models of autonomous robots implemented for Huawei's production base are of great reference value.

Mr. Guan Jian, Vice President of Go Further.AI, believes that with the acceleration of digital intelligence transformation and upgrading in the manufacturing industry, while the reduction of labor and the rise in labor costs, the traditional logistics operation model needs to be changed urgently, and the autonomous solution has gradually become the rigid demand of enterprises, with broad application prospects.

Go Further.AI has summarized the following pain points in the traditional logistics operation model of large factories.

Low logistics efficiency:Many factories operate in a more traditional logistics mode, relying mainly on manpower and simple machinery for cargo handling and distribution, which is inefficient and susceptible to perceived and environmental factors, making it impossible to achieve efficient logistics operations.

Non-standard warehousing management:There are non-standard warehousing management in manufacturing plants, resulting in inventory confusion, backlog of goods, expiration and other problems. At the same time, the lack of effective inventory control and early warning mechanisms leads to increased uncertainty in production and logistics plans.

Transportation process involves risks:In some complex environments, there are high risks to material safety and personal safety, especially at night and in extreme weather conditions such as heavy rain, high temperature, and heavy snow.

Intransparent logistics information:The logistics information management of many factories is relatively backward, unable to achieve real-time update and sharing of information, resulting in poor information transmission between various departments, affecting the synergy and efficiency of logistics operations.

Insufficient cloud data analytics capabilities:Many factories lack in-depth analysis and mining capabilities for logistics data, unable to provide strong data support for logistics optimization, which increases the difficulty of logistics improvement and makes it difficult to achieve continuous optimization.

Guan Jian told the 《Logistics Technology and Application》reporter that in response to the painpoints faced by manufacturing enterprises, Go Further.AI proposed a solution for autonomous distribution and shared transportation capacity - using autonomous robots to cover the whole scene of logistics and transportation in the factory area, and providing an intelligent scheduling system to realize the autonomous, digitized and standardized material transportation.

Compared with the traditional logistics operation mode of manufacturing enterprises, the autonomous robot logistics mode has the following advantages:

More Safety:Real-time monitoring of robot status, multiple safety mechanisms to ensure safety.

More economy:Optimize labor costs by 50%, reducing tranditional robot maintenance and energy consumption costs.

More efficiency:7x24 hours all-weather, full-process operation, multiple robots can be dispatched uniformly to achieve collaborative operation.

More reasonable:Achieve cloud data management, accurate and reliable, real-time analysis, and achieve unified management of enterprise data, which can provide strong data support for logistics optimization.

According to Guan Jian, Go Further.AI is the first Chinese enterprise to achieve the mass production of 1,000 autonomous robots, and to achieve large0scale and LiveOps. He said:" The reason why users choose Go Further.AI is that they are interested in the maturity of ouor autonomous robot technology, the flexibility and safety of the robot itself, which can support the management of intelligent devices in various operation modes, meet their actual needs, and help users build smart factories.

Huawei has reached two autonomous robot cooperation projects with Go Further.AI on how to make it easier for R&D personnel to transfer materials, how to make the logistics link in the production park simpler and more efficient, and how to use autonomous robots to create smart factory smart logistics to help reduce costs and increase efficiency.

Scenario 1: Huawei Dongguan R&D Base Delivery

Go Further.AI autonomous delivery robot is located in Huawei Songyan Institute

无人轻卡在华为生产基地的应用

1.Project Background

Under the general trend of digital transformation, Huawei hopes to change the traditional logistics model of the factory area, introduce artificial intelligence and driverless technology, open up the "last mile" of smart factory logistics, and achieve cost reduction and efficiency. Go Further.AI adopts the latest generation of L4-level autonomous light trucks "Runxiao" independently developed to help Huawei build a factory intelligent logistics system.

2.Solution

Eve autonomous light truck provides the automatic distribution of standard materials, pallets and other diverse robots, and realizes the automatic docking of the autonomous robot with the turntable and platform conveyor lines, so as to realize the complete autonomous distribution process; realize the collaborative operation of various autonomous robots, realize the real "joint operation" of factory logistics + logistics operations + intelligent production lines, and build a real autonomous, efficient and shared distribution model.

3.Project Highlights

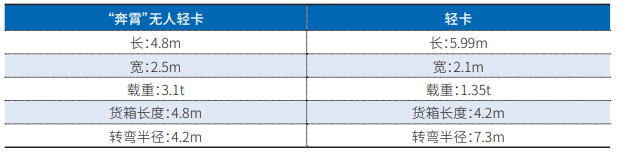

(1)"Eve" autonomous light truck, 4.8 meters cargo box can be loaded more:According to the "Technical Conditions for Motor robot Operation Safety", "Road Traffic Management Motor robot Types" and other regulations, the length of the light truck should be within 6m, and the maximum length of the cargo box should be 4.2m. The "Eve" autonomous light truck is based on self-driving ability, with four-wheel steering as the base, removing the cockpit, increasing the length of the cargo box, and greatly improving the robot loading capacity and transportation efficiency.

Comparison between "Eve" autonomous light truck and traditional light truck

(2)Precise docking, stable operation:Achieving accurate docking between autonomous robots and logistics center equipment is a technical challenge, requiring not only high-precision navigation and control, but also ensuring the stable operation of the autonomous robot system.

(3)Modular separation design of cabinet, lightweight design of carriage:Cabinets support the replacement of different types or cabinets according to business needs; further optimizing the compartment space and weight to ensure greater usable capacity and load.

(4)Four-wheel steering, two-way indiscriminate driving, wireless charging, to adapt to more complex scenarios in the factory:The autonomous light truck has higher flexibility, a smaller turning radius, and greatly reduces the area occupied by the site. The parking efficiency is increased by more than 50%, which can adapt to more complex environments in the factory. The contactless robot-grade wireless charging module can be charged in real time and efficiently during the loading process, achieving 7X24-hour full-process automation.

(5)Application of Automatic Docking Technology:Through high-precision navigation technology and sensing technology, human operation errors are reduced, the accuracy of docking is improved, and the fully automatic docking technology is used to complete the docking between the autonomous robot and the turntable or conveyor line in a short time, reducing manual intervention and improving the continuity of the production line.

(6)Integrity scheduling management system:Support the combination of automatic docking system and real-time monitoring system, capable of real-time monitoring of robot location, order status, etc.

4. Application Benefits

The factory is equipped with multiple "Eve" autonomous light trucks, which reduce labor costs and material loading and unloading time through fully automatic docking. It is estimated that the docking time can be shortened by an average of 20% in the future LiveOps, and the smooth operation of autonomous robots can reduce the accident rate by 50%. In the future, the fully automatic docking system will be further optimized, the application scenarios will be expanded, and the overall logistics operation level will be improved.

According to Guan Jian, autonomous driving technology has developed rapidly in the domestic market in recent years and has been applied in many industries such as transportation, logistics, agriculture, mining, airports, etc. In the field of manufacturing logistics, autonomous driving technology helps enterprises improve transportation efficiency, reduce operating costs and improve information level.

Relatively speaking, the technology of small autonomous distribution robots is more mature and more widely used, while the application of autonomous light trucks in manufacturing enterprises has just started. "Our company will not release the autonomous light truck manufacturing solution until the end of 2023. In fact, before this, the model has been successfully used in animal husbandry, power generation and other industries, especially in the park, and can completely replace the use of traditional light trucks," Guan Jian said.

He believes that the application trend of autonomous driving technology in the manufacturing industry will exhibit the following characteristics:

One is the autonomous logistics distribution. The application of autonomous driving technology in the field of logistics distribution will gradually become popular. In the future, autonomous robots will undertake the distribution tasks of manufacturing enterprises, achieve autonomous and efficient logistics, further reduce logistics costs and improve transportation efficiency.

The second is the integrated innovation of intelligent manufacturing. Autonomous driving technology will be deeply integrated with intelligent manufacturing technology to promote integrated innovation in the manufacturing industry. By building an intelligent manufacturing system, the production process will be digitized, intelligent and networked, creating an efficient, flexible and safe production model, and enhancing the core competitiveness of the manufacturing industry.

The third is the improvement of automation and intelligence. By introducing intelligent devices such as autonomous robots and robots, the production process can be automated and intelligent, and production efficiency and product quality can be improved.

Fourth, the popularity of customized production.The application of autonomous driving technology will promote the popularization of customized production in the manufacturing industry. By introducing intelligent manufacturing equipment and software systems, the digitization and intelligent upgrade of production lines can be realized to meet the individual needs of consumers and improve the added value and market competitiveness of products.

In the key opinion, the market application of autonomous driving technology is influenced by a number of factors, including government policies, the maturity and cost of autonomous driving technology, laws and regulations, road safety management, social acceptance, and industry standard setting.

It is reported that in the industrial field, there are dozens of autonomous driving technology suppliers in China, and different companies have chosen different tracks, such as ports, mines, airports, and trunk transportation. Go Further.AI's main business is concentrated in the two major segments of autonomous delivery robots in closed parks and express delivery autonomous robots on open roads.

As a leading R & D, manufacturing and operation service provider of autonomous logistics robots in China, Go Further.AI's core team comes from well-known universities and research institutes such as National University of Defense Technology, Tsinghua University, Peking University, etc., with more than 30 years of experience in driverless technology research and development and engineering research. The company has its own R & D centers and production plants in Changsha, Wuhu and other places, which can complete the R & D, design and overall processing of driverless car software and hardware and core components; has a dedicated platform test site, with the ability to test driverless car hardware and software platforms; and has the ability to empower various industries with autonomous driving kits.

Through the self-developed management platform, Go Further.AI has realized the commercial application of autonomous robots in multiple typical scenarios such as campuses, communities, scenic spots, parks, hospitals and health posts, with a total landing in more than 90 cities, and a cumulative distribution volume of more than 3.50 million pieces. The mileage of business operations exceeds 2.6 million km, and there are more than 600 partners, including JD.com, Meituan, Huawei, Foxconn, China Post, Industrial and Commercial Bank of China, Rakuten, State Grid, etc., especially the company's terminal autonomous distribution robot domestic market share is more than 30%. In addition, Go Further.AI is also a pioneer in the mass export of domestic autonomous robots overseas. It has reached cooperation with local enterprises such as the Netherlands, Japan, and South Korea, and has been well received by users.

Talking about the future planning of Go Further.AI in marketing activities and technological innovation, the key points are introduced from three aspects: market application, technological innovation and partners.

Market application direction:The company will continue to work on promoting the wide application of autonomous driving technology in different industries, especially in the industrial and logistics industries, providing comprehensive solutions to create a whole-process automation docking solution for users. Focus on customer satisfaction, focus on doing a good job in Client Server, and provide a full range of technical support and training to ensure that customers can make full use of autonomous driving technology to improve business efficiency and jointly achieve sustainable development in the field of smart logistics.

Technological innovation:Give full play to the company's capabilities in high-precision navigation, robot and robot R&D strength, autonomous robot control accuracy, sensitivity and consistency, and continue to invest in R & D and innovation to meet the diversity, stability and safety requirements of transported items in different application scenarios. At the same time, pay attention to and participate in the formulation and compliance of industry standards to ensure that the company's technology meets domestic and foreign regulations and standards.

Partners:We partner with robot manufacturers, logistics companies, urban planning departments, and other industries to promote the application of autonomous driving technology, and through collaborative innovation, we are committed to providing customers with more comprehensive, efficient, and intelligent solutions.

"The autonomous driving technology market is in a period of rapid growth, especially the demand for autonomous robots in the factory is growing very well. It is expected that the company's sales will double this year. With the significant increase in the number of projects, Xingshen Intelligence will further improve product quality and standardize project delivery management to better serve our customers." Guan Jian is confident about the future development.

+86 400-0731-233

consult@xingshentech.com

C3, Industry Creation Coalesce Changsha, No.77 South Section of No. 6 East Road, Economic and Technical Development Zone, Changsha 410100, Hunan Province, P.R. China

Copyright ©2023 Changsha Xingshen Intelligent Technology Co., Ltd 湘ICP备18006663号-1